Plasma Etching

NNF Staff Contacts : Jeff Ricker-Hagler

Oxford NGP80 RIE

Gases: CF4, CHF3, C2F6, SF6, Ar, O2

Standard Etches : SiO2, Si3N4, Glass, Si, and SiC

Samples : 1 – 4″ Wafer or Equivalent Area

Allowed Masking Materials: Photoresists and SU8

Etch rates, selectivity to photo-resist, uniformity and wall angle profile data:

A standard process for Si etching (Fluorine based) is checked weekly and data is

collected to observe and correct deviations >10%. Chamber cleaning, process

conditioning steps and MFC’s calibration are scheduled based on the data to

maintain equipment performance.

Calibration data can be viewed per power level: 120W, 170W, and 220W.

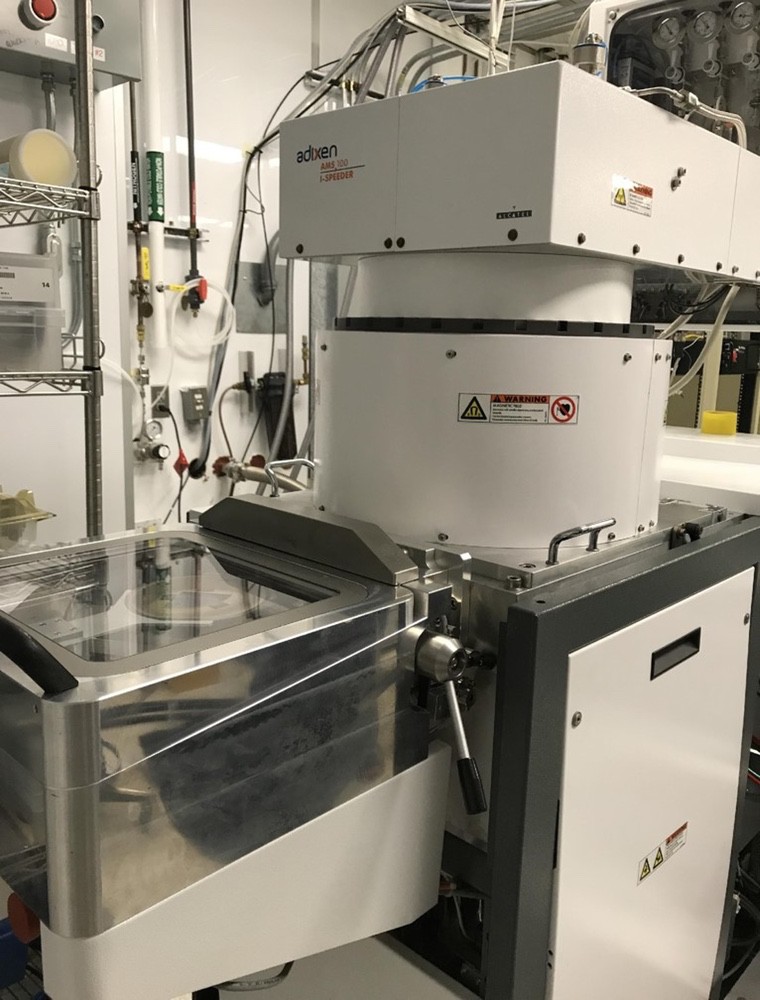

Alcatel Deep Reactive Ion Etch

Gases : SF6, C4F8, CF4, Ar, O2

Standard Etches : Si, Glass, SiO2

Samples : 1 – 6″ Wafer or Equivalent Area

Allowed Masking Materials : Photoresist, SU8, and Nickel

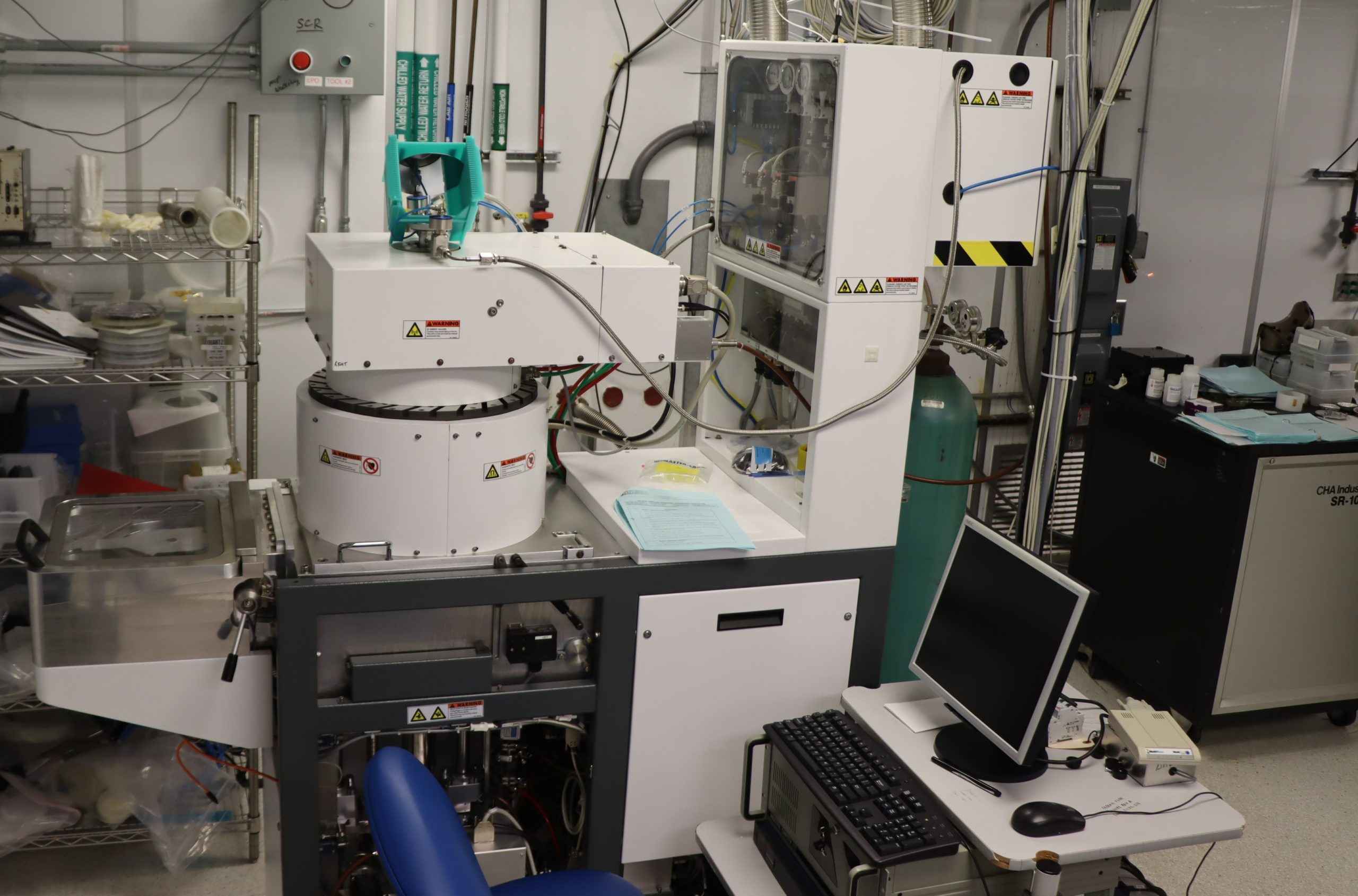

Oxford Plasmalab 100 ICP Etcher

Gases : BCl3, Cl2, SF6, O2, Ar, N2

Standard Etches : GaN, AlGaN

Samples : 1 – 6″ Wafer or Equivalent Area

Allowed Masking Materials : Photoresist and SU8

Etch rates, selectivity to photo-resist, uniformity and wall angle profile data:

A standard process for Si etching (Chlorine based) is checked weekly and data is

collected to observe and correct deviations >10%. Chamber cleaning, process

conditioning steps and MFC’s calibration are scheduled based on the data to

maintain equipment performance.

Calibration data can be viewed per pressure level: 15mTorr and 30mTorr.