Physical Vapor Deposition

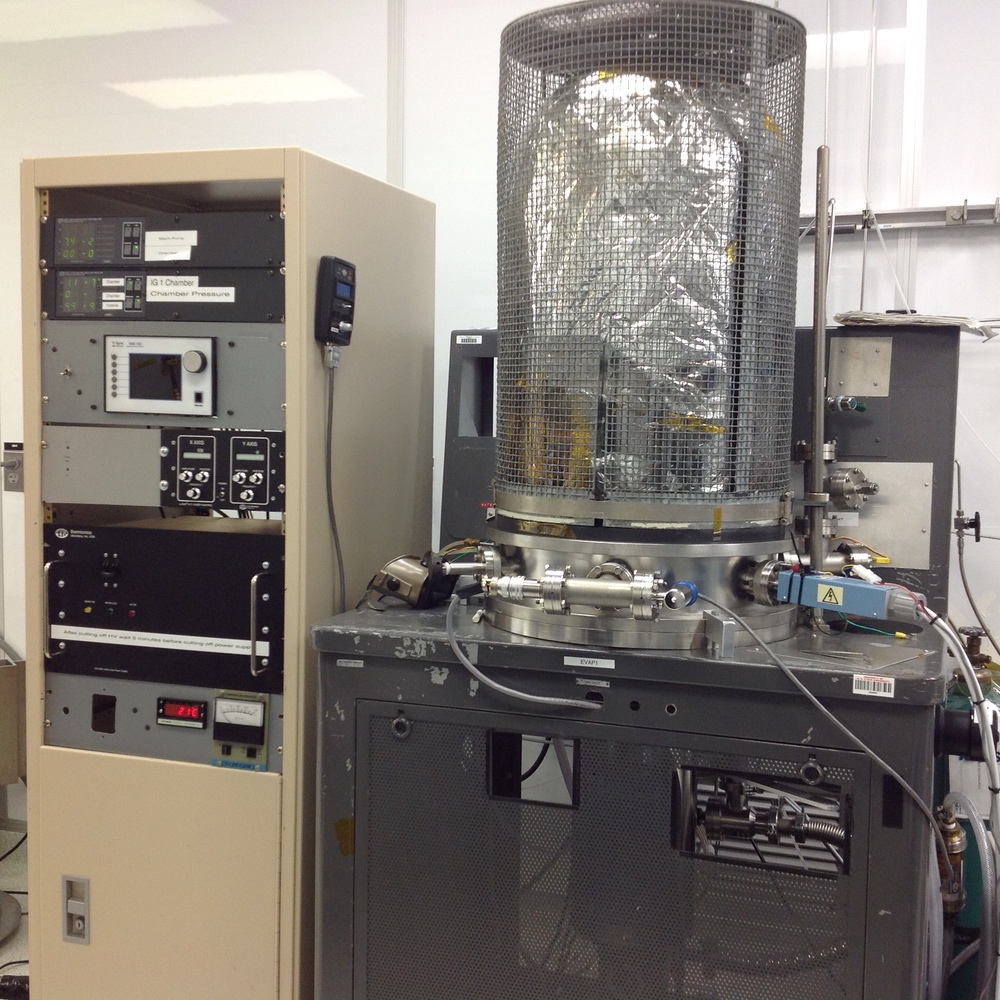

Thermionics Ebeam Evaporation – Staff Contact Nicole Hedges

Samples : 7 – 4″ Wafers or Equivalent Area

Approved Materials: Ti, Cr, Al, Ni, Cu, Au

2.2cc crucibles, 8 pocket rotary holder

Base Pressure ~ 2e-7 Torr; Pump Time ~ 15 minutes to low e-6 Torr

Metal Deposition Accuracy Checks:

The deposition accuracy of titanium is checked on a monthly basis. Other supported materials are checked quarterly.

100nm of material will be deposited on a single 5″ silicon wafer over the central holder location. The actual deposition thickness will be checked on the Dektak D150 in 4 locations on the wafer and averaged. Accuracy checks will be run until final deposited thickness is within +/- 5% of the target.

CHA Ebeam – Staff Contact Nicole Hedges

Samples : 12 – 4″ Wafers or Equivalent Area

Approved Materials : Al, Ni, Ti, Au, Pt, Pd

Automatic operation, 6 pocket rotary holder

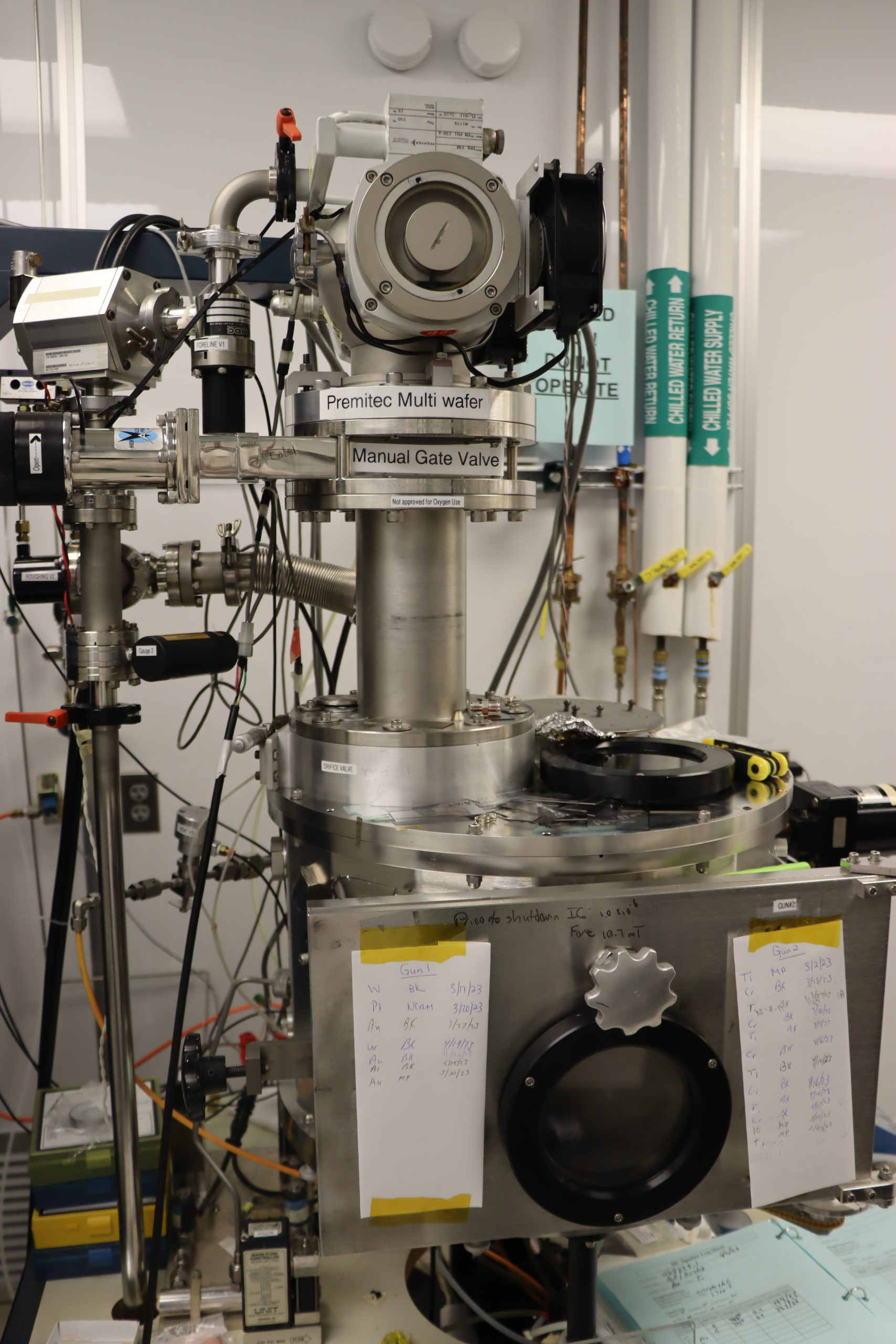

DC Sputter – Staff Contact Bill Kiether

Sample Sizes: 4 – 6″ wafers or equivalent area

Available Targets: Ti, Cr, W, Al, Cu, Au, and Pt

Base Pressure ~ 1.2e-6 Torr; Pump Time ~ 3 Hours

Operation Gas Flow ~ 50mT Argon

Glovebox Resistive Heated Evaporator – Staff Contact Nicole Hedges

Samples : 1 – 6″ Wafer or Equivalent Area

Approved Materials: Al, Ti, Ni, Mg, LiF

Available Boat : Tungsten

Base Pressure ~ Barr

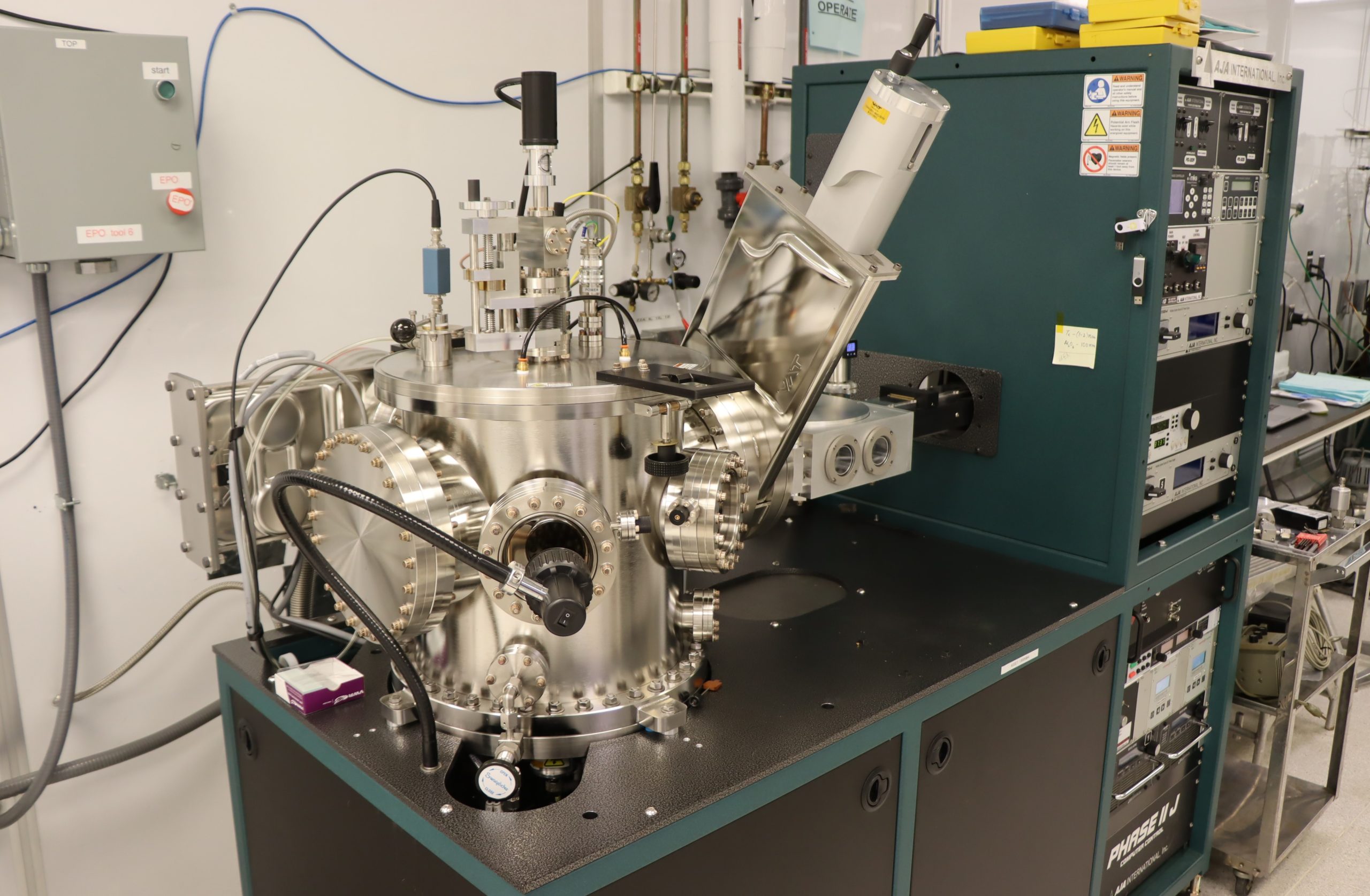

Orion Sputter Tool – Staff Contact Bill Kiether

Samples : 1 – 6″ Wafer or Equivalent Area

Approved Materials: Ti, Ni, Mo

Chamber guns: 5, 2″ guns

Gas Type: Ar

Submicron thin film physical vapor deposition